The International Atomic Energy Agency (IAEA) has invited Oxford Sigma to contribute to the effort to standardise small scale testing techniques for fusion materials qualification. Dr Thomas Davis, Oxford Sigma’s Chief Technology Officer, has been appointed a Scientific Investigator to the IAEA Coordinated Research Project (CRP) on the international standard for harmonisation of small specimen test techniques (SSTT) for fusion applications. SSTT is driven by the need to miniaturise materials specimens for neutron irradiation experiments, due to the limitation in irradiation volume. It is these experimental tests that are critical to underpinning the construction and safe operation of proposed advanced fission and commercial fusion power stations by the global industry.

Dr Davis’ 4-year role on the IAEA’s “Towards the Standardization of Small Specimen Test Techniques for Fusion Applications – Phase II” is to guide and provide expertise to ensure that the standard is fit for purpose in enabling nuclear code qualification of key fusion reduced-activation structural materials, such as EUROFER and F82H. These two steels are leading structural materials for fusion in-vessel components, such as divertors, breeder blankets, and first-wall structure. Dr Davis’ is a contributing member of the American Society of Mechanical Engineers (ASME)’s Boiler and Pressure Vessel Code (BPVC) III Division 4 (Rules for Construction of Fusion Energy Devices). Division 4 has been approved for publication in the ASME BPVC 2023 edition. He is the chairman of the ASME BPVC Section III Division 4 Special Working Group for Fusion Stakeholders.

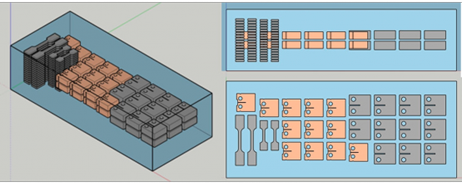

This co-ordinated research project seeks to provide a set of guidelines for SSTT based on common agreed best practices on main test techniques (tensile, creep, low cycle fatigue, fracture toughness, fatigue crack growth rate) for reference structural fusion materials to provide the basis for a full standardization of the SSTT. This effort already started in the earlier co-ordinated research project, Towards the Standardization of Small Specimen Test Techniques for Fusion Applications (F13017), which was concluded in 2021.

The specific Research Objectives are:

- Continuation of the supporting experimental programme (“Intercomparison exercise from different laboratories”) for the respective test methods. The focus is on the applicability of guidelines and methodologies drafted so far under high temperature conditions and suited for hot cell environment as well as closing gaps in the output of CRP F13017 that are specific for the respective test methods addressed.

- To establish reference guidelines for tensile, creep, low cycle fatigue, fracture toughness and fatigue crack growth rate tests using small specimens for RAFM steels. A focus will be on achieving a firm basis for test results at elevated temperatures. Formulation of guidelines will follow criteria and practice from well-established standards like ASTM or ISO.

- To establish guidelines for the use of SSTT taking into account the need of integrating these elements or data gathered from SSTT into nuclear code frameworks.

‘Commercial fusion power stations are on a critical pathway to enabling the carbon-free energy source which the world needs now more than ever. IAEA’s small specimen test techniques (SSTT) Coordinated Research Program is a key step in ensuring these commercial fusion power stations have access to fusion materials qualification for safe use by maximizing the potential of the limited availability of neutron irradiation sources worldwide. I am pleased to support this CRP in the production of a standard that can be used for materials qualification in appropriate codes and standards, such ASME BPVC.’

~ Dr Thomas Davis, CTO, Oxford Sigma

About Oxford Sigma

Oxford Sigma tackles energy security and climate change by accelerating the development of fusion and advanced nuclear energy. The company aims to develop enabling materials technologies in fusion energy, develop materials for extreme environments, and provides design services to accelerate and achieve commercialisation. Internationally recognised as a highly technical SME, our growing team of engineers and scientists play an active role in the emerging supply chain ecosystem within the UK, USA and EU for fusion energy and advanced nuclear energy. Please do get in touch at [email protected]