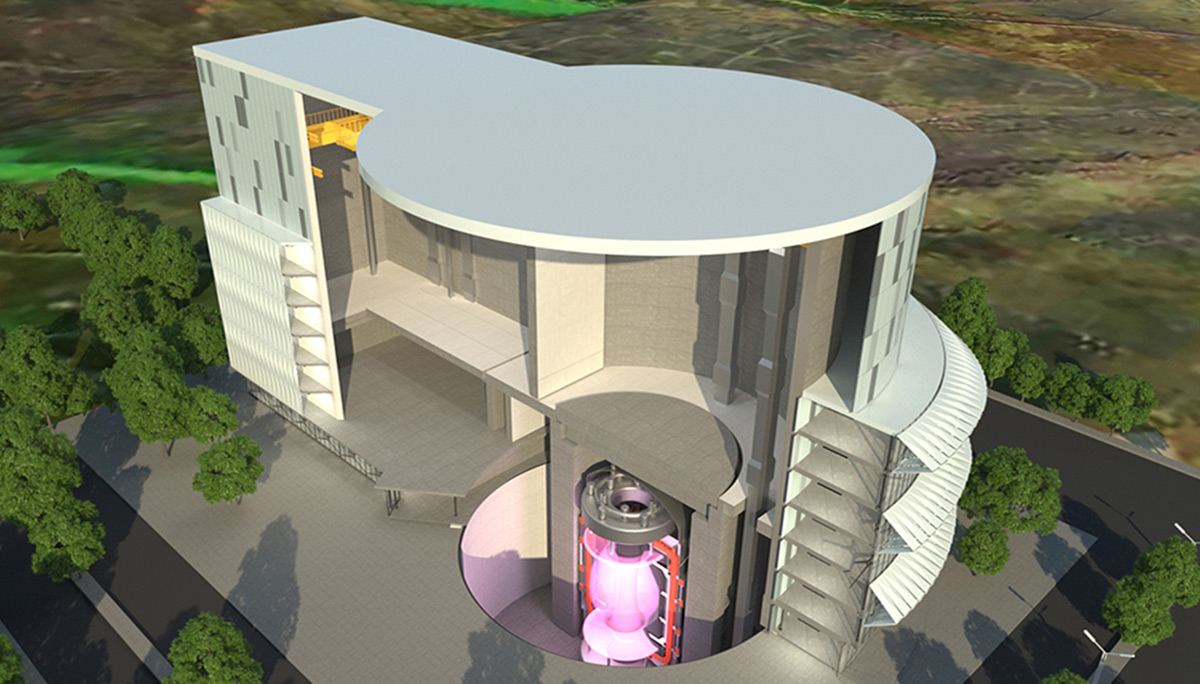

UKAEA and Oxford Sigma have teamed up to develop manufacturing pathway solutions for novel tungsten plasma-facing components for the UK Atomic Energy Authority (UKAEA)’s Spherical Tokamak for Energy Production (STEP) programme. This ambitious programme seeks to demonstrate the commercial viability of fusion energy.

The plasma-facing components of a fusion energy machine must protect the rest of the components from the extreme heat loads and neutron damage imparted by the plasma. It is an actively cooled component often containing sacrificial sections that are designed to melt during occurrences when the plasma touches the wall. Traditional plasma-facing component designs consisting of tungsten armour on a steel or copper heatsink present many manufacturing challenges for implementation on a large-scale tokamak, like STEP, mainly due to the materials’ differences in heat expansion coefficients and thermal heat conductivity properties. Oxford Sigma has identified suitable manufacturing pathways for using novel tungsten alloys for the complex plasma-facing component design. These novel tungsten alloys could eliminate the need for challenging dissimilar material joins and be included in future fusion power stations like STEP to improve the performance and operational lifetime of the plasma-facing components.

The Oxford Sigma team are experts in fusion materials and are developing novel materials solution for fusion components, such as first-walls and breeder blankets. The company is leading the development of the ASME BPVC fusion construction code and collaborating with multiple national laboratories on the standardisation of fusion materials qualification. This collaboration between Oxford Sigma and UKAEA demonstrates the growth and maturity in engineering design of fusion in the UK with the aim of an accelerated commercialisation by 2040.

‘The advanced materials and geometries that may be required for devices in STEP present serious challenges, and opportunities for manufacturing. We are delighted to have been able to support UKAEA in exploring their methods of manufacture for these components.‘

~ Dr Alasdair Morrison, Technology Manager

‘There are a number of significant engineering and manufacturing challenges to resolve to realise fusion, alongside the science of fusion itself. Our work with Oxford Sigma will start to address some of these challenges, building on existing knowledge to positively influence component design to ensure manufacturability.‘

~ Karyn Eden, UKAEA’s STEP Manufacturing Readiness Lead

About UK Atomic Energy Authority

United Kingdom Atomic Energy Authority (UKAEA) is the UK’s national organisation responsible for the research and delivery of sustainable fusion energy. It is an executive non-departmental public body, sponsored by the Department for Energy Security and Net Zero.

Fusion energy has great potential to deliver safe, sustainable, low carbon energy for generations to come. It is based on the same processes that power the Sun and stars, and would form part of the world’s future energy mix. Achieving this is a major technical challenge that involves working at the forefront of science, engineering, and technology.

UKAEA’s programmes include the MAST-Upgrade (Mega Amp Spherical Tokamak) fusion experiment and the JET (Joint European Torus) fusion research facility. JET is operated by UKAEA at its Culham Campus near Oxford, on behalf of EUROfusion scientists and engineers.

STEP (Spherical Tokamak for Energy Production) is UKAEA’s ambitious programme to accelerate the delivery of fusion energy, with plans to deliver a prototype powerplant producing net electricity in the 2040s in Nottinghamshire.

In 2021, UKAEA opened its Fusion Technology Facility near Rotherham in South Yorkshire, to develop and test materials and components for future fusion powerplants.

UKAEA also undertakes cutting edge work with academia, other research organisations and the industrial supply chain in a wide spectrum of areas, including robotics and materials.

More information: https://www.gov.uk/ukaea. Social Media: @UKAEAofficial

About STEP

Through the STEP programme UKAEA is working on the delivery a fusion powerplant prototype targeting 2040 for delivery of fusion derived electrical power onto the nation grid. As well as delivering this prototype powerplant STEP is also acting as a catalyst to build a workforce within the UK with the skills required to design, build and operate such powerplants and to become leaders in the field of fusion energy production. For further information please visit us at www.step.ukaea.uk

About Oxford Sigma

Oxford Sigma tackles energy security and climate change by accelerating the commercialisation of fusion energy. Oxford Sigma’s mission is to deliver materials technology, materials solutions, and fusion design services in order to accelerate the commercialisation of fusion energy. Oxford Sigma is internationally recognised as a key fusion materials and technological leader within the market. The company operates in the United States, United Kingdom, European Union, Canada, and Japan.

Get in touch at [email protected]