Oxford Sigma has published its research on optimising the lifetime of tungsten plasma-facing components in future fusion power plants with a peer-reviewed publication titled “Suppression of Rhenium and Osmium Production in Tungsten by Selective Isotopic Enrichment.” The research has been in collaboration with Dr Matthew Lloyd of the University of Birmingham and Singapore University of Technology and Design.

The scientific publication is found in the Fusion Engineering and Design journal. It provides the first stage proof of concept of the team’s optimisation. The publication is available here and cited as:

Anderton, et al. Fusion Engineering and Design 197 (2023) 114073This publication supports Oxford Sigma’s recent patent on isotopic tailoring of tungsten for fusion.

Nuclear fusion has the potential to become a carbon-free, abundant energy source for both the electricity and hydrogen market of the future. A fusion power station will require the use of plasma facing components that shield the machines’ structural components from fusion plasma erosion, high temperatures and radiation damage.

One outstanding functional materials challenge for fusion energy is the plasma-facing components (PFCs) material’s selection. Fusion plasma temperatures of up to 109 °C require PFC materials to operate with temperatures in excess of 1000 °C under normal operation, and potentially higher during off-normal events. In addition, fusion plasmas produce high energy neutrons that pass through the wall material, interacting with the nuclei within the material’s structure, producing displacements and transmutation of isotopes. Tungsten is the leading PFC material choice because it meets the materials requirements for PFCs by possessing a high melting temperature (3422 °C), a high thermal conductivity, high plasma sputtering threshold, and a high temperature operational window.

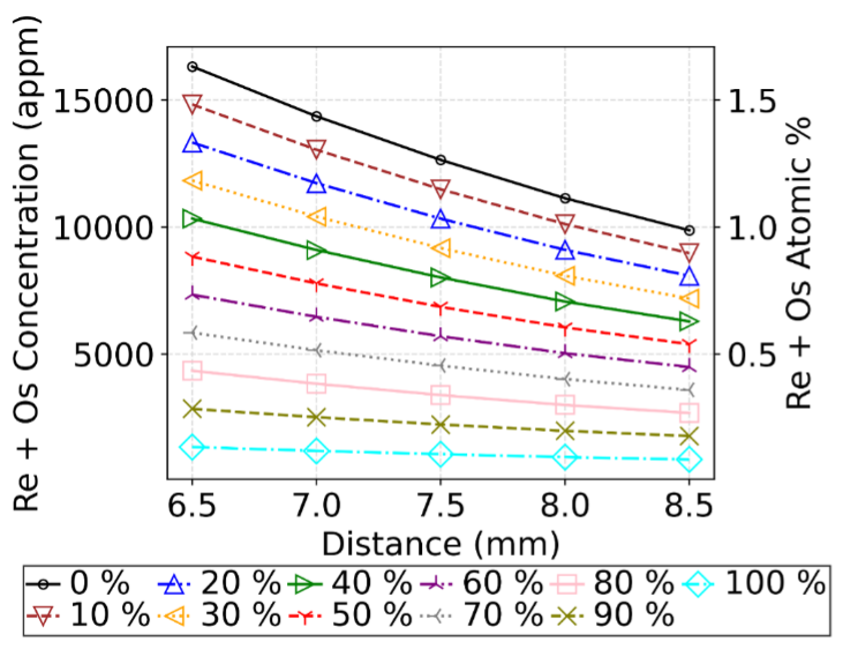

A side effect of the use of tungsten in neutron irradiation environments such as fusion is the transmutation to rhenium and osmium, which are known to degrade the mechanical and thermal properties. In Oxford Sigma’s research, nuclear simulations were used to investigate a strategy of selective isotopic enrichment and/or depletion of tungsten isotopes to supress the formation of rhenium and osmium in a representative first-wall monoblock design. The research found that rhenium and osmium production can be reduced by up to three orders of magnitude compared to natural tungsten by depleting tungsten-186 isotope. This work is part of a wider strategy within Oxford Sigma to develop material solutions for fusion power stations.

“Oxford Sigma is striving to provide optimisations for issues which present significant challenges to the deployment of commercial fusion energy. This research is a step towards improving component lifetimes and reducing waste in future fusion reactors, thus making fusion more sustainable commercial option.”

~ Mark Anderton, Nuclear Engineer, Oxford Sigma.

“Novel materials are required to tackle the extreme conditions in fusion reactors. This proof-of-concept study undertaken in collaboration with Oxford Sigma explores an exciting avenue for supressing the production of detrimental elements under irradiation“

~ Dr Matthew Lloyd, Research Fellow at University of Birmingham.

Oxford Sigma tackles energy security and climate change by accelerating the commercialisation of fusion energy. Oxford Sigma’s mission is to deliver materials technology, materials solutions, and fusion design services in order to accelerate the commercialisation of fusion energy. Oxford Sigma is internationally recognised as a key fusion materials and technological leader within the market.

Get in touch at [email protected]