Oxford Sigma has been awarded a highly competitive contract worth £1.49m from United Kingdom Atomic Energy Authority (UKAEA) to develop innovative technologies for fusion energy, which promises to be a safe, low carbon and sustainable part of the world’s future energy supply.

Project LiFTOFF (Lithium Facility by Oxford Sigma for Fusion) has been awarded to Oxford Sigma through the UKAEA Fusion Industry Programme. This Programme forms part of the Government’s support for the UK’s fusion industry by developing the necessary technology and skills for the future global fusion power plant market.

Oxford Sigma are developing a liquid lithium loop facility to evaluate the impact of liquid lithium exposure on materials used in breeder blanket components, critical for the design and commercialisation of fusion power devices.

The contract has strong partnerships with Bangor University, First Light Fusion, The University of Birmingham, and Nuvia who are providing key expertise, experience, and resources to the team.

“Delivering fusion energy is one of the great scientific and engineering challenges of our time. The Fusion Industry Programme is supporting businesses to overcome these challenges and help make fusion a commercial reality. These organisations have been awarded contracts after successfully demonstrating the feasibility of their concepts through earlier stages of the Fusion Industry Programme and will now develop their technologies to the ‘proof of concept’ stage.”

~ Tim Bestwick, UKAEA’s Chief Development Officer

“LiFTOFF will play a key part in the development of fusion energy by enabling advancement in the necessary materials knowledge needed for engineering design and qualification of materials for powerplants. Moreover, it is a necessary step in the maturation of fusion energy, to deliver the new engineering knowledge and material solutions that are necessary for successful commercial deployment. We are proud that our technology has been supported through the Fusion Industry Programme’s second phase and are looking forward to building the necessary technology solutions and know-how through this ‘proof-of-concept’ stage with our formidable partners.”

~ Dr Alasdair Morrison, Oxford Sigma’s Technology Manager

“This project works towards de-risking the engineering and design of a fusion power plant, and First Light is delighted to be a part of it. If we are to put commercial fusion energy on the grid as quickly as possible, we must tackle the engineering challenges as well as the core physics of fusion. First Light is pursuing plans for the development of a power plant in the 2030s.”

~ Jorge Fradera, Head of Power Plant at First Light Fusion

“Bangor University are excited to be part of this team developing systems to make fusion power possible. Our experience with Liquid Metal systems and fundamental fusion materials development is being accelerated and leveraged by the excellent team that Oxford-Sigma has assembled.“

~ Professor Simon Middleburgh, of the Nuclear Futures Institute at Bangor University

“Nuvia are delighted to continue our relationship with Oxford Sigma in developing liquid lithium testing capabilities within the UK, collaborating across industry and academia to tackle a key fusion industry challenge and provide a route to enabling low carbon energy production.”

~ Adrian Davis-Johnston, Head of Research, Development and Innovation at Nuvia

“The development of liquid lithium testing capabilities and new high-performance materials is critical to the realisation of fusion energy. The University of Birmingham and Sandy Knowles’ Materials for Extremes group are proud to be a part of the LiFTOFF team that are tackling this important challenge. We look forward working with industry and academia in the team Oxford Sigma have assembled to accelerate the development of exciting new materials.”

~ Dr Matthew Lloyd, Research Fellow at the School of Metallurgy and Materials, University of Birmingham.

LiFTOFF seeks to evaluate the effect of liquid lithium exposure on both corrosion resistance and mechanical performance of different materials that will be used in breeder blanket materials. Nuclear fusion requires two hydrogen isotopes as fuel: deuterium and tritium. Deuterium can be easily extracted from seawater (about 33g per tonne) while tritium is rare and difficult to source due to its short half-life (12.3 years). Therefore, tritium is proposed to be bred inside the fusion reactor in a component called breeder blanket.

To produce tritium, liquid lithium must be exposed to neutrons coming from the fusion reactions and must be contained in the breeder blanket for further separation from the remaining lithium. How the liquid lithium interacts and degrades the mechanical performance of the breeder blanket components could largely determine the success of commercial fusion power plants.

The present project will develop a liquid lithium loop facility able to expose materials to similar conditions that will be faced in breeder blankets, raise the TRL of Oxford Sigma’s proprietary liquid lithium resistant materials, and establish a lithium corrosion database.

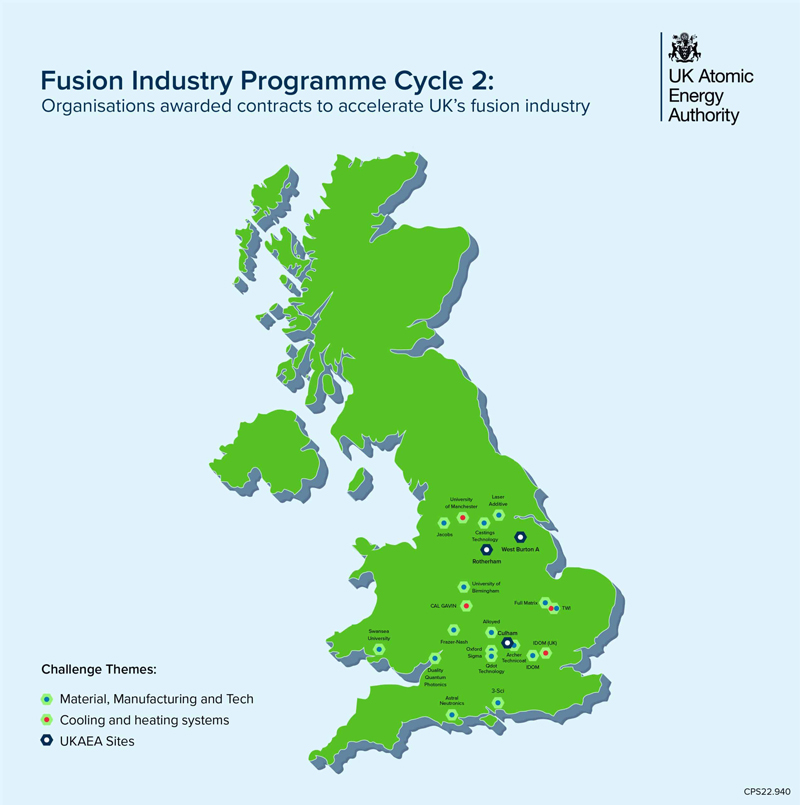

Map of Fusion Industry Programme contract recipients

If your company or institution is interested in liquid lithium materials compatibility or other materials related topics, please do reach out to Oxford Sigma on [email protected].