Materials for Fusion

Approaches to fusion energy

Fusion systems have unique materials challenges to create sustainable, performing, and predictable characteristics to unlock the technology as a carbon-free energy source.

We focus on producing sustainable, integrated materials for pilot and commercial fusion power stations in order to accelerate the energy source, covering inertial confinement, tokamaks, stellarators, field-reversed configuration, and many others.

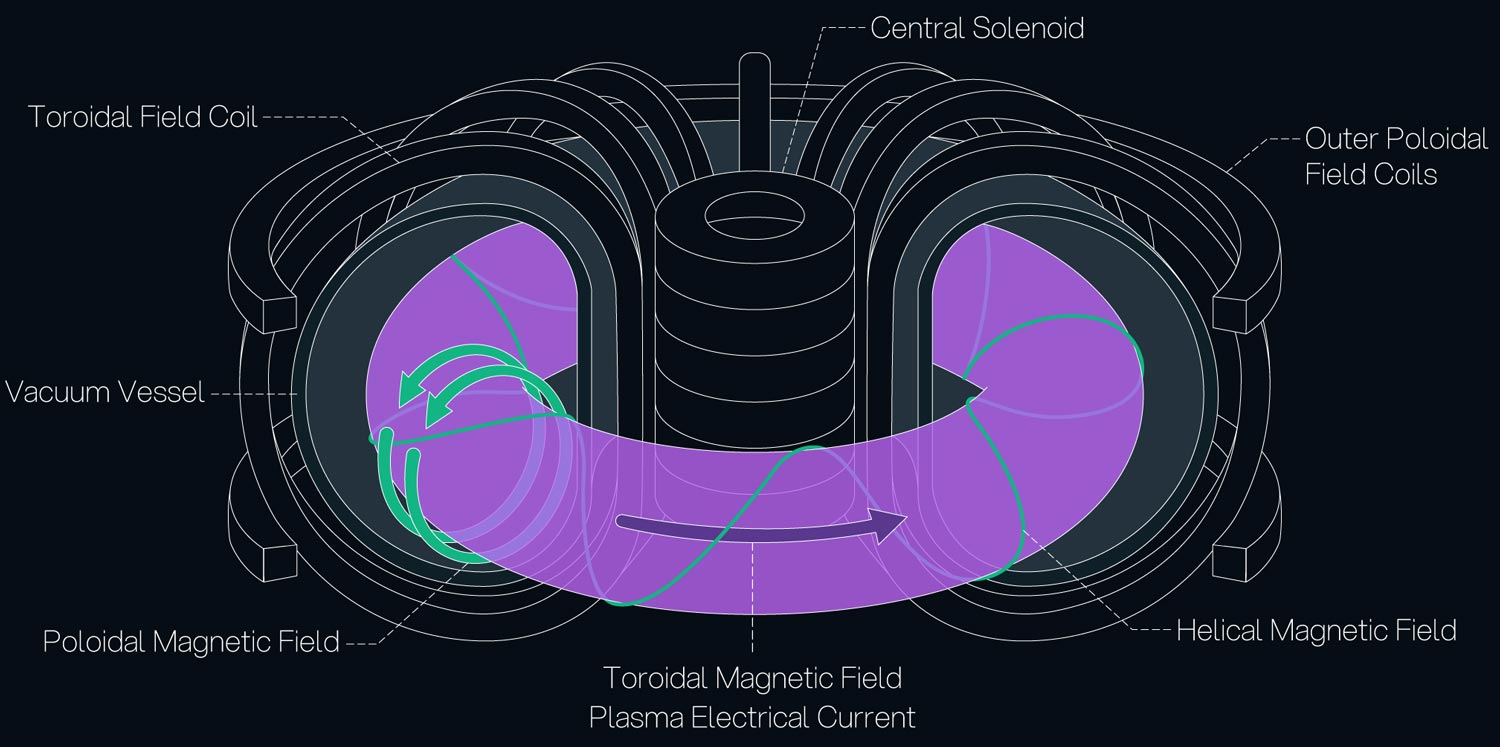

Conventional Tokamak

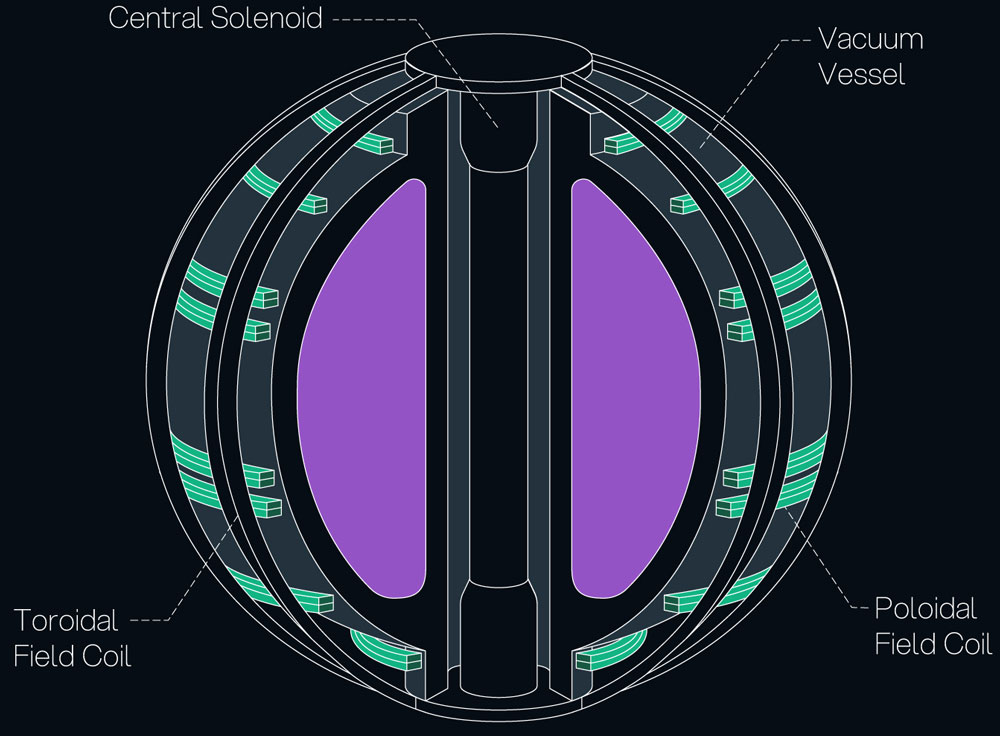

Spherical Tokamak

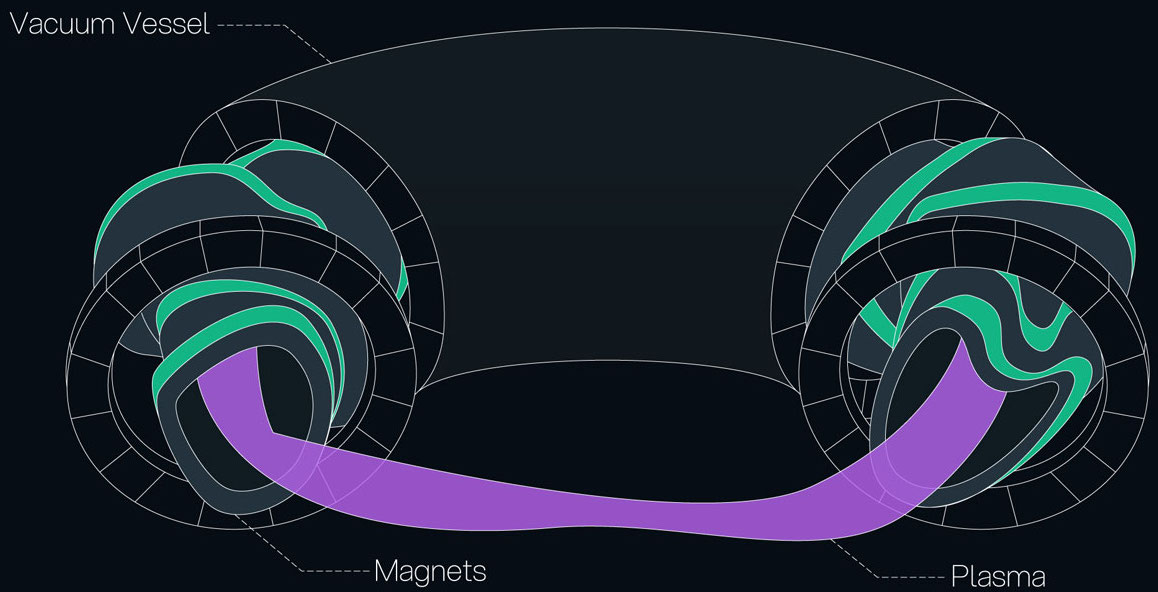

Stellarator

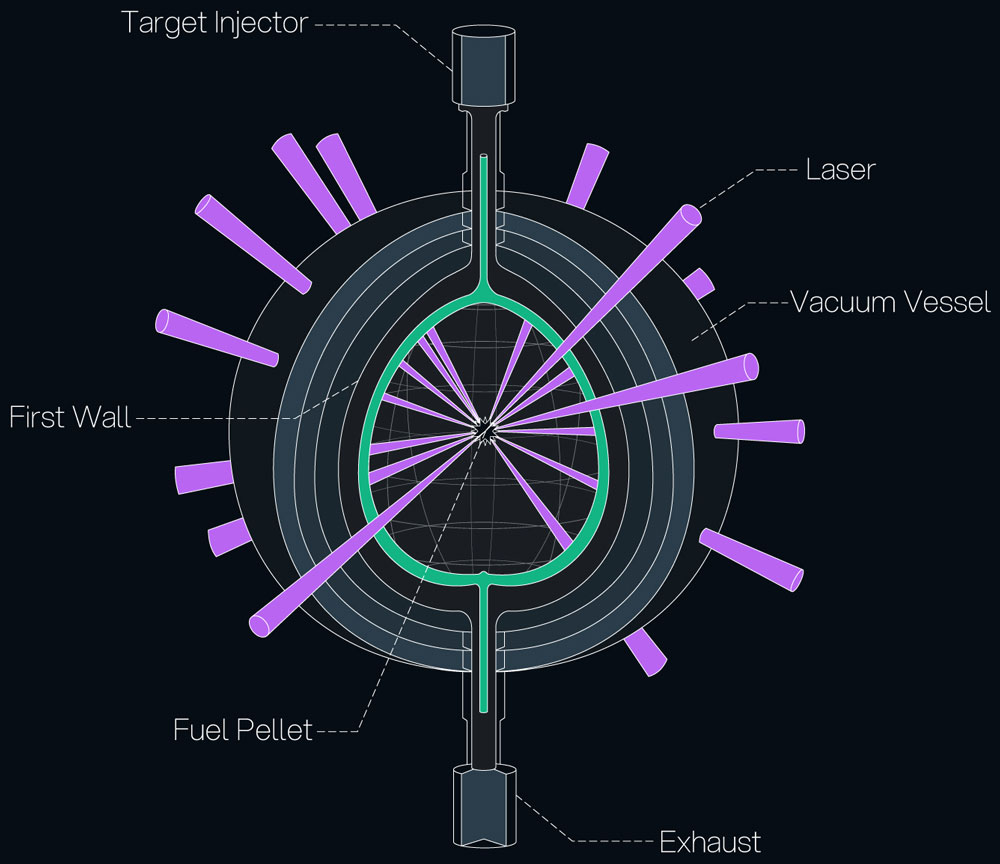

Inertial Confinement

Our ecosystem

Oxford Sigma aims to produce materials technology for fusion that utilises our ecosystem model where our solutions possess the following characteristics:

Our approach

Oxford Sigma believes that materials technology is key to the acceptance of fusion. To ensure this can be realised, we focus on:

Fusion Materials Engineering by applying agnostic approaches to ensure promising candidates

Leading qualification of fusion pressure vessels by contributing to the ASME BPVC Section III Division 4 “Fusion Energy Devices” construction code and standard

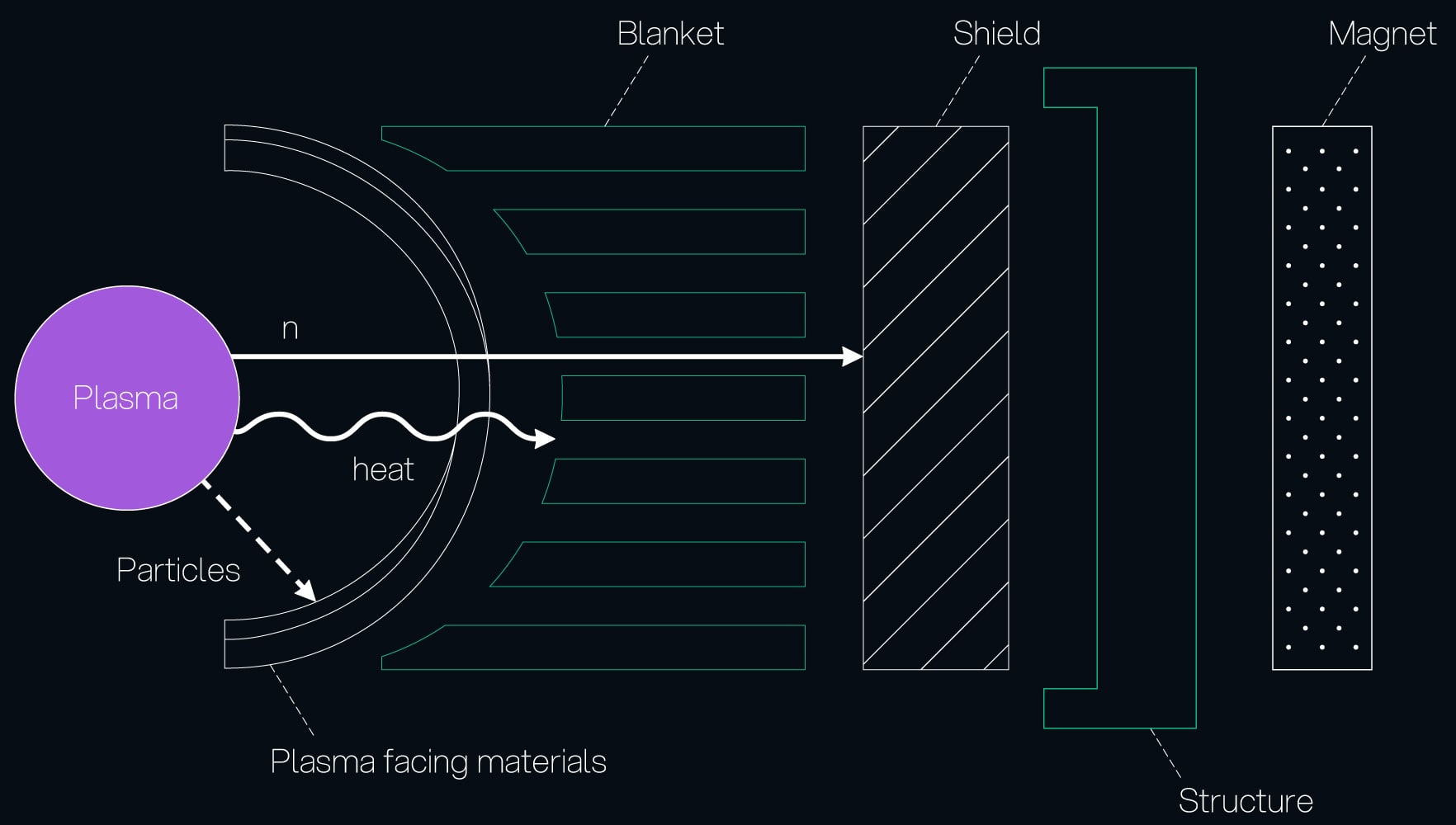

Leading Fusion Component Design such as first-wall structures and blankets

Regulatory Compliance where suitable routes for meeting standards and reliability is at the core

Experts on radiation damage in functional and structural materials, covering neutron, ion, plasma, and gamma-ray doses

Developing novel Magnetohydrodynamics models for liquid metal blankets to de-risk our technology

We believe our integrated approach yields realistic materials for fusion energy. Oxford Sigma technologies are integrated across the fusion core: